Fluoropolymer Processing Aid Market Analysis By Application (Automotive and Transportation, Electronics and Electrical, Building and Construction, Pharmaceuticals, Others), By Type (External Lubricants, Internal Lubricants, Others), and By Region Forecast to 2032

- Report ID: ME_00132399

- Format: Electronic (PDF)

- Publish Type: Publish

- Number of Pages: 250

Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 8.89 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The Fluoropolymer Processing Aid Market size is estimated to grow at a CAGR of 5.3% between 2023 and 2032. The growth of the market depends on several factors, including the rising demand for high-performance plastics, increasing adoption of fluoropolymers in various industries, and the need for enhanced processing efficiency in polymer manufacturing. Fluoropolymer processing aids are specialized additives used in the production of fluoropolymers to improve their processing characteristics and final product quality.

Fluoropolymer Processing Aid Market Overview:

Drivers:

One of the key drivers of the Fluoropolymer Processing Aid market growth is the increasing demand for high-performance plastics. Fluoropolymers are known for their exceptional properties, including high-temperature resistance, chemical resistance, low friction, and electrical insulation. These properties make fluoropolymers a preferred choice in industries such as automotive, electronics, and construction. The growing application of fluoropolymers in these sectors drives the demand for fluoropolymer processing aids to optimize manufacturing processes and enhance product quality.

Additionally, the adoption of fluoropolymers in various industries, including pharmaceuticals, food processing, and semiconductor manufacturing, is contributing to market growth. Fluoropolymers are used in critical applications where the highest level of purity and performance is required. The incorporation of processing aids ensures the efficient processing of these materials, further fueling market expansion.

Trends:

A significant trend shaping the Fluoropolymer Processing Aid market growth is the development of advanced and eco-friendly processing aid formulations. With increasing environmental regulations and consumer demand for sustainable products, manufacturers are focusing on creating processing aids that are not only effective but also environmentally friendly. Bio-based and non-toxic processing aids are gaining traction as they align with the sustainability goals of many industries.

Moreover, there is a trend toward customized processing aid solutions tailored to specific fluoropolymer formulations and processing requirements. This customization allows manufacturers to optimize their production processes, reduce waste, and improve the overall efficiency of fluoropolymer manufacturing.

Restraints:

The high cost of fluoropolymer processing aids can be a limiting factor for market growth. Fluoropolymers themselves are premium materials, and the addition of specialized processing aids can further increase production costs. This cost factor can pose challenges for small and medium-sized enterprises (SMEs) and industries with tight budget constraints, potentially limiting their adoption of fluoropolymers and processing aids.

Additionally, the availability of alternative materials and processing methods can impact the demand for fluoropolymers and their associated processing aids. In some applications, alternative polymers or additives may offer cost-effective solutions that compete with fluoropolymers, affecting market growth.

Fluoropolymer Processing Aid Market Segmentation By Application:

The automotive and transportation segment is estimated to witness significant growth during the forecast period within the Fluoropolymer Processing Aid market. Fluoropolymers are widely used in the automotive industry due to their excellent chemical resistance, electrical insulation properties, and low friction characteristics. They find applications in components such as fuel lines, wiring, gaskets, and seals. The incorporation of fluoropolymer processing aids ensures the efficient and cost-effective production of these critical automotive components.

Furthermore, the electronics and electrical segment represents another crucial application area for Fluoropolymer Processing Aid. As the electronics industry demands smaller and more complex components, fluoropolymers play a vital role in insulating and protecting electronic circuits. Processing aids assist in achieving precise molding and extrusion of these intricate parts.

Fluoropolymer Processing Aid Market Segmentation By Type:

The demand for external lubricants as fluoropolymer processing aids is on the rise, contributing to the growth of the external lubricant segment. External lubricants are used to reduce friction and enhance the flow properties of fluoropolymer materials during processing. These additives facilitate smoother extrusion, injection molding, and other manufacturing processes.

Moreover, the internal lubricant segment is also experiencing growth as manufacturers seek to improve the dispersion of fillers and pigments in fluoropolymers. Internal lubricants help prevent agglomeration of additives, ensuring uniform product quality and performance.

Regional Overview:

Download the report summary now!

Request pdf Sample

Regions with a strong presence of industries that rely on high-performance plastics, such as North America and Europe, are expected to contribute significantly to the Fluoropolymer Processing Aid market during the forecast period. The automotive and electronics sectors in these regions are key consumers of fluoropolymers, driving the demand for processing aids to optimize production processes.

Furthermore, regions with expanding chemical and manufacturing industries, including Asia-Pacific, are witnessing increased adoption of fluoropolymers and processing aids. Growing industrialization, urbanization, and infrastructure development in countries like China and India are driving the need for high-performance materials, boosting market growth.

In recent years, there has been a growing emphasis on sustainability and environmental protection in various regions, which is expected to lead to the development and adoption of eco-friendly processing aids in the Fluoropolymer Processing Aid market.

Fluoropolymer Processing Aid Market Customer Landscape:

The Fluoropolymer Processing Aid market analysis includes various customer segments, including polymer manufacturers, compounders, and end-users across industries such as automotive, electronics, and healthcare. Understanding the needs and preferences of these stakeholders is essential for developing tailored solutions and maintaining strong customer relationships.

Major Fluoropolymer Processing Aid Market Companies:

Market players in the Fluoropolymer Processing Aid industry are continuously innovating to provide efficient and sustainable processing aid solutions. Some major companies operating in this market include:

- Solvay SA

- 3M Company

- Shamrock Technologies

- Asahi Glass Co., Ltd.

- DuPont de Nemours, Inc.

- Arkema Group

- AGC Chemicals

- Micro Powders, Inc.

- Dyneon LLC (3M)

- Chemours Company

- Daikin Industries, Ltd.

- The Chemours Company

- RAGNI Enterprises

These companies offer a wide range of processing aid products designed to meet the specific requirements of fluoropolymer manufacturers and end-users.

Segment Overview:

The Fluoropolymer Processing Aid market report offers revenue forecasts at the global, regional, and country levels, along with an analysis of trends and growth opportunities from 2019 to 2032.

Application Outlook (USD Million, 2019 - 2032):

- Automotive and Transportation

- Electronics and Electrical

- Building and Construction

- Pharmaceuticals

- Others

Type Outlook (USD Million, 2019 - 2032):

- External Lubricants

- Internal Lubricants

- Others

Geography Outlook (USD Million, 2019 - 2032):

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- South America

- Brazil

- Argentina

- Chile

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

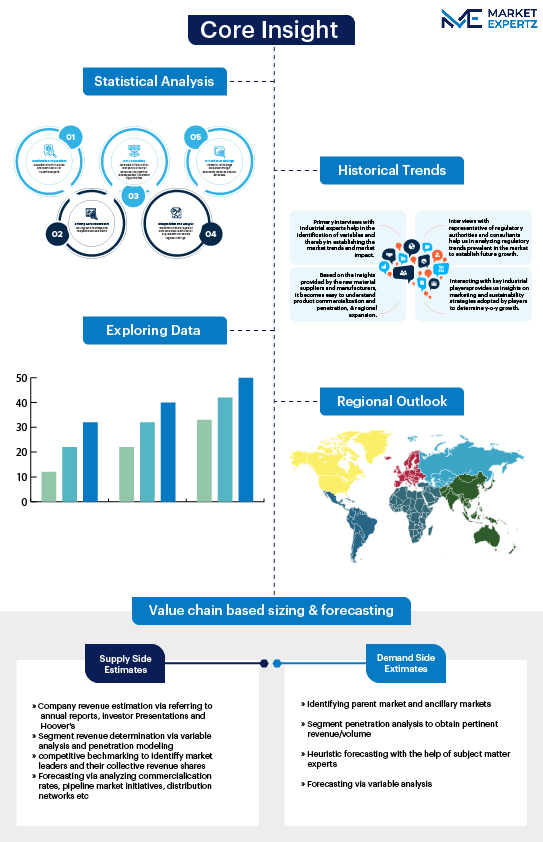

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"