Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 8.45 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

Thermoplastic Polymer Pipe Coating Market Analysis Report 2023-2032:

The Thermoplastic Polymer Pipe Coating Market size is estimated to grow at a CAGR of 6.78% between 2022 and 2032. The market size is forecast to increase by USD 2,345.67 million. The growth of the market depends on several factors, including the increasing demand for corrosion protection in the oil and gas industry, the growing infrastructure development in emerging economies, and the rising adoption of thermoplastic polymer coatings in various industries. Thermoplastic polymer pipe coating refers to a protective layer applied to pipes to prevent corrosion and extend their lifespan. It involves the application of thermoplastic polymers, such as polyethylene, polypropylene, and polyvinyl chloride, onto the surface of pipes using various coating techniques. The coating provides excellent resistance to chemicals, abrasion, and impact, making it suitable for a wide range of applications in industries such as oil and gas, water and wastewater, and chemical processing.

Thermoplastic Polymer Pipe Coating Market Overview

Drivers

One of the key factors driving the thermoplastic polymer pipe coating market growth is the increasing demand for corrosion protection in the oil and gas industry. Pipelines used in the oil and gas industry are exposed to harsh environments, including corrosive substances and extreme temperatures. The application of thermoplastic polymer coatings on these pipelines provides excellent corrosion resistance, protecting them from degradation and extending their lifespan. As a result, there is a growing demand for thermoplastic polymer pipe coatings in the oil and gas industry to ensure the safe and efficient transportation of oil, gas, and other fluids.

Moreover, the growing infrastructure development in emerging economies is also fueling the market growth. Rapid urbanization and industrialization in countries such as China, India, and Brazil have led to increased investments in infrastructure projects, including the construction of pipelines for water supply, sewage systems, and transportation of various fluids. Thermoplastic polymer pipe coatings are widely used in these projects to provide corrosion protection and ensure the longevity of the pipelines. Therefore, the increasing infrastructure development activities are driving the demand for thermoplastic polymer pipe coatings.

Trends

A key trend shaping the thermoplastic polymer pipe coating market growth is the rising adoption of thermoplastic polymer coatings in various industries. Thermoplastic polymers offer several advantages over traditional coating materials, such as epoxy and polyurethane. They have excellent chemical resistance, high impact strength, and good adhesion to different substrates. These properties make them suitable for a wide range of applications in industries such as water and wastewater, chemical processing, and mining. The increasing awareness about the benefits of thermoplastic polymer coatings and their superior performance characteristics are driving their adoption in various industries, thereby fueling the market growth.

Additionally, the development of advanced coating techniques and technologies is also contributing to the market growth. Manufacturers are investing in research and development activities to enhance the performance and application efficiency of thermoplastic polymer coatings. For instance, the development of fusion-bonded epoxy (FBE) powder coatings and extrusion coatings has revolutionized the pipe coating industry by providing improved corrosion protection and ease of application. These advancements in coating technologies are driving the adoption of thermoplastic polymer pipe coatings in different industries.

Restraints:

One of the key challenges hindering the thermoplastic polymer pipe coating market growth is the high cost of raw materials. Thermoplastic polymers, such as polyethylene and polypropylene, are derived from petrochemical feedstocks, and their prices are subject to fluctuations in crude oil prices. The volatility in raw material prices can significantly impact the overall cost of thermoplastic polymer pipe coatings, making them expensive compared to other coating materials. This can pose a challenge for small and medium-sized enterprises with limited budgets, limiting their adoption of thermoplastic polymer coatings.

Furthermore, the stringent environmental regulations regarding the use of certain chemicals in thermoplastic polymer coatings can also hinder the market growth. Some thermoplastic polymers contain additives or processing aids that may be restricted or regulated due to their potential environmental and health impacts. Compliance with these regulations can increase the complexity and cost of manufacturing thermoplastic polymer pipe coatings. Therefore, the regulatory landscape poses a challenge for manufacturers in terms of product development and market expansion.

Thermoplastic Polymer Pipe Coating Market Segmentation By Application

The oil and gas industry segment is estimated to witness significant growth during the forecast period. Thermoplastic polymer pipe coatings play a crucial role in protecting pipelines used in the oil and gas industry from corrosion and other forms of degradation. These pipelines are exposed to harsh environments, including corrosive substances, high temperatures, and mechanical stresses. The application of thermoplastic polymer coatings provides excellent resistance to corrosion, abrasion, and impact, ensuring the integrity and longevity of the pipelines. Therefore, there is a growing demand for thermoplastic polymer pipe coatings in the oil and gas industry to ensure the safe and efficient transportation of oil, gas, and other fluids.

The water and wastewater segment is also expected to contribute significantly to the market growth. Thermoplastic polymer pipe coatings are widely used in water and wastewater infrastructure projects to protect pipelines from corrosion and extend their lifespan. The coatings provide excellent resistance to chemicals and abrasion, ensuring the durability and reliability of the pipelines in harsh environments. With the increasing focus on water conservation and the development of water treatment facilities, there is a growing demand for thermoplastic polymer pipe coatings in the water and wastewater industry.

Thermoplastic Polymer Pipe Coating Market Segmentation By Type

The polyethylene segment is estimated to witness significant growth during the forecast period. Polyethylene is one of the most commonly used thermoplastic polymers for pipe coating applications due to its excellent chemical resistance, high impact strength, and good adhesion to different substrates. It provides superior corrosion protection and durability, making it suitable for a wide range of applications in industries such as oil and gas, water and wastewater, and chemical processing. The increasing demand for polyethylene pipe coatings in various industries is driving the growth of this segment.

Regional Overview

North America is estimated to contribute significantly to the growth of the global market during the forecast period. The region has a well-established oil and gas industry, which is one of the major consumers of thermoplastic polymer pipe coatings. The increasing investments in pipeline infrastructure projects, especially in the United States and Canada, are driving the demand for thermoplastic polymer coatings in the region. Additionally, the growing focus on environmental sustainability and the need for corrosion protection in water and wastewater infrastructure projects are further fueling the market growth in North America.

Europe is also expected to witness significant growth in the thermoplastic polymer pipe coating market. The region has a mature industrial sector, including oil and gas, water and wastewater, and chemical processing industries, which are major consumers of thermoplastic polymer coatings. The stringent environmental regulations in Europe regarding the use of coating materials with low environmental impact are driving the adoption of thermoplastic polymer pipe coatings. The increasing investments in infrastructure development and the emphasis on sustainable solutions are further contributing to the market growth in Europe.

Thermoplastic Polymer Pipe Coating Market Customer Landscape

The thermoplastic polymer pipe coating market industry report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their growth strategies.

Who are the Major Thermoplastic Polymer Pipe Coating Market Companies?

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Some of the major companies operating in the thermoplastic polymer pipe coating market are:

- 3M Company

- Akzo Nobel N.V.

- Arkema Group

- BASF SE

- Covestro AG

- Dow Inc.

- Evonik Industries AG

- PPG Industries, Inc.

- Sherwin-Williams Company

- Solvay SA

The research report also includes detailed analyses of the competitive landscape of the market and information about 20 market companies, including:

- Aditya Birla Chemicals

- Akzo Nobel N.V.

- Arkema Group

- Axalta Coating Systems Ltd.

- BASF SE

- Covestro AG

- Dow Inc.

- Evonik Industries AG

- Hempel A/S

- Jotun A/S

- Kansai Paint Co., Ltd.

- PPG Industries, Inc.

- RPM International Inc.

- Sherwin-Williams Company

- Solvay SA

- The Chemours Company

- The Valspar Corporation

- Tikkurila Oyj

- Wacker Chemie AG

- Yokohama Rubber Co., Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data

Segment Overview

Geography Outlook (USD Million, 2019 - 2032):

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- South America

- Chile

- Argentina

- Brazil

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Table of Contents

Global Thermoplastic Polymer Pipe Coating Market Professional Survey Report 2017

1 Industry Overview of Thermoplastic Polymer Pipe Coating

1.1 Definition and Specifications of Thermoplastic Polymer Pipe Coating

1.1.1 Definition of Thermoplastic Polymer Pipe Coating

1.1.2 Specifications of Thermoplastic Polymer Pipe Coating

1.2 Classification of Thermoplastic Polymer Pipe Coating

1.2.1 Podwer

1.2.2 Foam

1.3 Applications of Thermoplastic Polymer Pipe Coating

1.3.1 Oil & Gas

1.3.2 Water & Wastewater Treatment

1.3.3 Chemical Processing

1.3.4 Others

1.4 Market Segment by Regions

1.4.1 North America

1.4.2 China

1.4.3 Europe

1.4.4 Southeast Asia

1.4.5 Japan

1.4.6 India

2 Manufacturing Cost Structure Analysis of Thermoplastic Polymer Pipe Coating

2.1 Raw Material and Suppliers

2.2 Manufacturing Cost Structure Analysis of Thermoplastic Polymer Pipe Coating

2.3 Manufacturing Process Analysis of Thermoplastic Polymer Pipe Coating

2.4 Industry Chain Structure of Thermoplastic Polymer Pipe Coating

3 Technical Data and Manufacturing Plants Analysis of Thermoplastic Polymer Pipe Coating

3.1 Capacity and Commercial Production Date of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

3.2 Manufacturing Plants Distribution of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

3.3 R&D Status and Technology Source of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

3.4 Raw Materials Sources Analysis of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

4 Global Thermoplastic Polymer Pipe Coating Overall Market Overview

4.1 2012-2017E Overall Market Analysis

4.2 Capacity Analysis

4.2.1 2012-2017E Global Thermoplastic Polymer Pipe Coating Capacity and Growth Rate Analysis

4.2.2 2016 Thermoplastic Polymer Pipe Coating Capacity Analysis (Company Segment)

4.3 Sales Analysis

4.3.1 2012-2017E Global Thermoplastic Polymer Pipe Coating Sales and Growth Rate Analysis

4.3.2 2016 Thermoplastic Polymer Pipe Coating Sales Analysis (Company Segment)

4.4 Sales Price Analysis

4.4.1 2012-2017E Global Thermoplastic Polymer Pipe Coating Sales Price

4.4.2 2016 Thermoplastic Polymer Pipe Coating Sales Price Analysis (Company Segment)

5 Thermoplastic Polymer Pipe Coating Regional Market Analysis

5.1 North America Thermoplastic Polymer Pipe Coating Market Analysis

5.1.1 North America Thermoplastic Polymer Pipe Coating Market Overview

5.1.2 North America 2012-2017E Thermoplastic Polymer Pipe Coating Local Supply, Import, Export, Local Consumption Analysis

5.1.3 North America 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price Analysis

5.1.4 North America 2016 Thermoplastic Polymer Pipe Coating Market Share Analysis

5.2 China Thermoplastic Polymer Pipe Coating Market Analysis

5.2.1 China Thermoplastic Polymer Pipe Coating Market Overview

5.2.2 China 2012-2017E Thermoplastic Polymer Pipe Coating Local Supply, Import, Export, Local Consumption Analysis

5.2.3 China 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price Analysis

5.2.4 China 2016 Thermoplastic Polymer Pipe Coating Market Share Analysis

5.3 Europe Thermoplastic Polymer Pipe Coating Market Analysis

5.3.1 Europe Thermoplastic Polymer Pipe Coating Market Overview

5.3.2 Europe 2012-2017E Thermoplastic Polymer Pipe Coating Local Supply, Import, Export, Local Consumption Analysis

5.3.3 Europe 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price Analysis

5.3.4 Europe 2016 Thermoplastic Polymer Pipe Coating Market Share Analysis

5.4 Southeast Asia Thermoplastic Polymer Pipe Coating Market Analysis

5.4.1 Southeast Asia Thermoplastic Polymer Pipe Coating Market Overview

5.4.2 Southeast Asia 2012-2017E Thermoplastic Polymer Pipe Coating Local Supply, Import, Export, Local Consumption Analysis

5.4.3 Southeast Asia 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price Analysis

5.4.4 Southeast Asia 2016 Thermoplastic Polymer Pipe Coating Market Share Analysis

5.5 Japan Thermoplastic Polymer Pipe Coating Market Analysis

5.5.1 Japan Thermoplastic Polymer Pipe Coating Market Overview

5.5.2 Japan 2012-2017E Thermoplastic Polymer Pipe Coating Local Supply, Import, Export, Local Consumption Analysis

5.5.3 Japan 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price Analysis

5.5.4 Japan 2016 Thermoplastic Polymer Pipe Coating Market Share Analysis

5.6 India Thermoplastic Polymer Pipe Coating Market Analysis

5.6.1 India Thermoplastic Polymer Pipe Coating Market Overview

5.6.2 India 2012-2017E Thermoplastic Polymer Pipe Coating Local Supply, Import, Export, Local Consumption Analysis

5.6.3 India 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price Analysis

5.6.4 India 2016 Thermoplastic Polymer Pipe Coating Market Share Analysis

6 Global 2012-2017E Thermoplastic Polymer Pipe Coating Segment Market Analysis (by Type)

6.1 Global 2012-2017E Thermoplastic Polymer Pipe Coating Sales by Type

6.2 Different Types of Thermoplastic Polymer Pipe Coating Product Interview Price Analysis

6.3 Different Types of Thermoplastic Polymer Pipe Coating Product Driving Factors Analysis

6.3.1 Podwer of Thermoplastic Polymer Pipe Coating Growth Driving Factor Analysis

6.3.2 Foam of Thermoplastic Polymer Pipe Coating Growth Driving Factor Analysis

7 Global 2012-2017E Thermoplastic Polymer Pipe Coating Segment Market Analysis (by Application)

7.1 Global 2012-2017E Thermoplastic Polymer Pipe Coating Consumption by Application

7.2 Different Application of Thermoplastic Polymer Pipe Coating Product Interview Price Analysis

7.3 Different Application of Thermoplastic Polymer Pipe Coating Product Driving Factors Analysis

7.3.1 Oil & Gas of Thermoplastic Polymer Pipe Coating Growth Driving Factor Analysis

7.3.2 Water & Wastewater Treatment of Thermoplastic Polymer Pipe Coating Growth Driving Factor Analysis

7.3.3 Chemical Processing of Thermoplastic Polymer Pipe Coating Growth Driving Factor Analysis

7.3.4 Others of Thermoplastic Polymer Pipe Coating Growth Driving Factor Analysis

8 Major Manufacturers Analysis of Thermoplastic Polymer Pipe Coating

8.1 PPG Industries, Inc. (U.S.)

8.1.1 Company Profile

8.1.2 Product Picture and Specifications

8.1.2.1 Product A

8.1.2.2 Product B

8.1.3 PPG Industries, Inc. (U.S.) 2016 Thermoplastic Polymer Pipe Coating Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.1.4 PPG Industries, Inc. (U.S.) 2016 Thermoplastic Polymer Pipe Coating Business Region Distribution Analysis

8.2 Akzo Nobel N. V. (The Netherlands)

8.2.1 Company Profile

8.2.2 Product Picture and Specifications

8.2.2.1 Product A

8.2.2.2 Product B

8.2.3 Akzo Nobel N. V. (The Netherlands) 2016 Thermoplastic Polymer Pipe Coating Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.2.4 Akzo Nobel N. V. (The Netherlands) 2016 Thermoplastic Polymer Pipe Coating Business Region Distribution Analysis

8.3 The Sherwin-Williams Company (U.S.)

8.3.1 Company Profile

8.3.2 Product Picture and Specifications

8.3.2.1 Product A

8.3.2.2 Product B

8.3.3 The Sherwin-Williams Company (U.S.) 2016 Thermoplastic Polymer Pipe Coating Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.3.4 The Sherwin-Williams Company (U.S.) 2016 Thermoplastic Polymer Pipe Coating Business Region Distribution Analysis

8.4 The Valspar Corporation (U.S.)

8.4.1 Company Profile

8.4.2 Product Picture and Specifications

8.4.2.1 Product A

8.4.2.2 Product B

8.4.3 The Valspar Corporation (U.S.) 2016 Thermoplastic Polymer Pipe Coating Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.4.4 The Valspar Corporation (U.S.) 2016 Thermoplastic Polymer Pipe Coating Business Region Distribution Analysis

8.5 Axalta Coating Systems Ltd. (U.S.)

8.5.1 Company Profile

8.5.2 Product Picture and Specifications

8.5.2.1 Product A

8.5.2.2 Product B

8.5.3 Axalta Coating Systems Ltd. (U.S.) 2016 Thermoplastic Polymer Pipe Coating Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.5.4 Axalta Coating Systems Ltd. (U.S.) 2016 Thermoplastic Polymer Pipe Coating Business Region Distribution Analysis

9 Development Trend of Analysis of Thermoplastic Polymer Pipe Coating Market

9.1 Global Thermoplastic Polymer Pipe Coating Market Trend Analysis

9.1.1 Global 2017-2022 Thermoplastic Polymer Pipe Coating Market Size (Volume and Value) Forecast

9.1.2 Global 2017-2022 Thermoplastic Polymer Pipe Coating Sales Price Forecast

9.2 Thermoplastic Polymer Pipe Coating Regional Market Trend

9.2.1 North America 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Forecast

9.2.2 China 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Forecast

9.2.3 Europe 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Forecast

9.2.4 Southeast Asia 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Forecast

9.2.5 Japan 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Forecast

9.2.6 India 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Forecast

9.3 Thermoplastic Polymer Pipe Coating Market Trend (Product Type)

9.4 Thermoplastic Polymer Pipe Coating Market Trend (Application)

10 Thermoplastic Polymer Pipe Coating Marketing Type Analysis

10.1 Thermoplastic Polymer Pipe Coating Regional Marketing Type Analysis

10.2 Thermoplastic Polymer Pipe Coating International Trade Type Analysis

10.3 Traders or Distributors with Contact Information of Thermoplastic Polymer Pipe Coating by Region

10.4 Thermoplastic Polymer Pipe Coating Supply Chain Analysis

11 Consumers Analysis of Thermoplastic Polymer Pipe Coating

11.1 Consumer 1 Analysis

11.2 Consumer 2 Analysis

11.3 Consumer 3 Analysis

11.4 Consumer 4 Analysis

12 Conclusion of the Global Thermoplastic Polymer Pipe Coating Market Professional Survey Report 2017

Methodology

Analyst Introduction

Data Source

List of Tables and Figures

Figure Picture of Thermoplastic Polymer Pipe Coating

Table Product Specifications of Thermoplastic Polymer Pipe Coating

Table Classification of Thermoplastic Polymer Pipe Coating

Figure Global Production Market Share of Thermoplastic Polymer Pipe Coating by Type in 2016

Figure Podwer Picture

Table Major Manufacturers of Podwer

Figure Foam Picture

Table Major Manufacturers of Foam

Table Applications of Thermoplastic Polymer Pipe Coating

Figure Global Consumption Volume Market Share of Thermoplastic Polymer Pipe Coating by Application in 2016

Figure Oil & Gas Examples

Table Major Consumers in Oil & Gas

Figure Water & Wastewater Treatment Examples

Table Major Consumers in Water & Wastewater Treatment

Figure Chemical Processing Examples

Table Major Consumers in Chemical Processing

Figure Others Examples

Table Major Consumers in Others

Figure Market Share of Thermoplastic Polymer Pipe Coating by Regions

Figure North America Thermoplastic Polymer Pipe Coating Market Size (Million USD) (2012-2022)

Figure China Thermoplastic Polymer Pipe Coating Market Size (Million USD) (2012-2022)

Figure Europe Thermoplastic Polymer Pipe Coating Market Size (Million USD) (2012-2022)

Figure Southeast Asia Thermoplastic Polymer Pipe Coating Market Size (Million USD) (2012-2022)

Figure Japan Thermoplastic Polymer Pipe Coating Market Size (Million USD) (2012-2022)

Figure India Thermoplastic Polymer Pipe Coating Market Size (Million USD) (2012-2022)

Table Thermoplastic Polymer Pipe Coating Raw Material and Suppliers

Table Manufacturing Cost Structure Analysis of Thermoplastic Polymer Pipe Coating in 2016

Figure Manufacturing Process Analysis of Thermoplastic Polymer Pipe Coating

Figure Industry Chain Structure of Thermoplastic Polymer Pipe Coating

Table Capacity and Commercial Production Date of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

Table Manufacturing Plants Distribution of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

Table R&D Status and Technology Source of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

Table Raw Materials Sources Analysis of Global Thermoplastic Polymer Pipe Coating Major Manufacturers in 2016

Table Global Capacity, Sales , Price, Cost, Sales Revenue (M USD) and Gross Margin of Thermoplastic Polymer Pipe Coating 2012-2017

Figure Global 2012-2017E Thermoplastic Polymer Pipe Coating Market Size (Volume) and Growth Rate

Figure Global 2012-2017E Thermoplastic Polymer Pipe Coating Market Size (Value) and Growth Rate

Table 2012-2017E Global Thermoplastic Polymer Pipe Coating Capacity and Growth Rate

Table 2016 Global Thermoplastic Polymer Pipe Coating Capacity (K MT) List (Company Segment)

Table 2012-2017E Global Thermoplastic Polymer Pipe Coating Sales (K MT) and Growth Rate

Table 2016 Global Thermoplastic Polymer Pipe Coating Sales (K MT) List (Company Segment)

Table 2012-2017E Global Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Table 2016 Global Thermoplastic Polymer Pipe Coating Sales Price (USD/MT) List (Company Segment)

Figure North America Capacity Overview

Table North America Supply, Import, Export and Consumption (K MT) of Thermoplastic Polymer Pipe Coating 2012-2017E

Figure North America 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Figure North America 2016 Thermoplastic Polymer Pipe Coating Sales Market Share

Figure China Capacity Overview

Table China Supply, Import, Export and Consumption (K MT) of Thermoplastic Polymer Pipe Coating 2012-2017E

Figure China 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Figure China 2016 Thermoplastic Polymer Pipe Coating Sales Market Share

Figure Europe Capacity Overview

Table Europe Supply, Import, Export and Consumption (K MT) of Thermoplastic Polymer Pipe Coating 2012-2017E

Figure Europe 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Figure Europe 2016 Thermoplastic Polymer Pipe Coating Sales Market Share

Figure Southeast Asia Capacity Overview

Table Southeast Asia Supply, Import, Export and Consumption (K MT) of Thermoplastic Polymer Pipe Coating 2012-2017E

Figure Southeast Asia 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Figure Southeast Asia 2016 Thermoplastic Polymer Pipe Coating Sales Market Share

Figure Japan Capacity Overview

Table Japan Supply, Import, Export and Consumption (K MT) of Thermoplastic Polymer Pipe Coating 2012-2017E

Figure Japan 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Figure Japan 2016 Thermoplastic Polymer Pipe Coating Sales Market Share

Figure India Capacity Overview

Table India Supply, Import, Export and Consumption (K MT) of Thermoplastic Polymer Pipe Coating 2012-2017E

Figure India 2012-2017E Thermoplastic Polymer Pipe Coating Sales Price (USD/MT)

Figure India 2016 Thermoplastic Polymer Pipe Coating Sales Market Share

Table Global 2012-2017E Thermoplastic Polymer Pipe Coating Sales (K MT) by Type

Table Different Types Thermoplastic Polymer Pipe Coating Product Interview Price

Table Global 2012-2017E Thermoplastic Polymer Pipe Coating Sales (K MT) by Application

Table Different Application Thermoplastic Polymer Pipe Coating Product Interview Price

Table PPG Industries, Inc. (U.S.) Information List

Table Product A Overview

Table Product B Overview

Table 2016 PPG Industries, Inc. (U.S.) Thermoplastic Polymer Pipe Coating Revenue (Million USD), Sales (K MT), Ex-factory Price (USD/MT)

Figure 2016 PPG Industries, Inc. (U.S.) Thermoplastic Polymer Pipe Coating Business Region Distribution

Table Akzo Nobel N. V. (The Netherlands) Information List

Table Product A Overview

Table Product B Overview

Table 2016 Akzo Nobel N. V. (The Netherlands) Thermoplastic Polymer Pipe Coating Revenue (Million USD), Sales (K MT), Ex-factory Price (USD/MT)

Figure 2016 Akzo Nobel N. V. (The Netherlands) Thermoplastic Polymer Pipe Coating Business Region Distribution

Table The Sherwin-Williams Company (U.S.) Information List

Table Product A Overview

Table Product B Overview

Table 2015 The Sherwin-Williams Company (U.S.) Thermoplastic Polymer Pipe Coating Revenue (Million USD), Sales (K MT), Ex-factory Price (USD/MT)

Figure 2016 The Sherwin-Williams Company (U.S.) Thermoplastic Polymer Pipe Coating Business Region Distribution

Table The Valspar Corporation (U.S.) Information List

Table Product A Overview

Table Product B Overview

Table 2016 The Valspar Corporation (U.S.) Thermoplastic Polymer Pipe Coating Revenue (Million USD), Sales (K MT), Ex-factory Price (USD/MT)

Figure 2016 The Valspar Corporation (U.S.) Thermoplastic Polymer Pipe Coating Business Region Distribution

Table Axalta Coating Systems Ltd. (U.S.) Information List

Table Product A Overview

Table Product B Overview

Table 2016 Axalta Coating Systems Ltd. (U.S.) Thermoplastic Polymer Pipe Coating Revenue (Million USD), Sales (K MT), Ex-factory Price (USD/MT)

Figure 2016 Axalta Coating Systems Ltd. (U.S.) Thermoplastic Polymer Pipe Coating Business Region Distribution

Figure Global 2017-2022 Thermoplastic Polymer Pipe Coating Market Size (K MT) and Growth Rate Forecast

Figure Global 2017-2022 Thermoplastic Polymer Pipe Coating Market Size (Million USD) and Growth Rate Forecast

Figure Global 2017-2022 Thermoplastic Polymer Pipe Coating Sales Price (USD/MT) Forecast

Figure North America 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Volume (K MT) and Growth Rate Forecast

Figure China 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Volume (K MT) and Growth Rate Forecast

Figure Europe 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Volume (K MT) and Growth Rate Forecast

Figure Southeast Asia 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Volume (K MT) and Growth Rate Forecast

Figure Japan 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Volume (K MT) and Growth Rate Forecast

Figure India 2017-2022 Thermoplastic Polymer Pipe Coating Consumption Volume (K MT) and Growth Rate Forecast

Table Global Sales Volume (K MT) of Thermoplastic Polymer Pipe Coating by Type 2017-2022

Table Global Consumption Volume (K MT) of Thermoplastic Polymer Pipe Coating by Application 2017-2022

Table Traders or Distributors with Contact Information of Thermoplastic Polymer Pipe Coating by Region

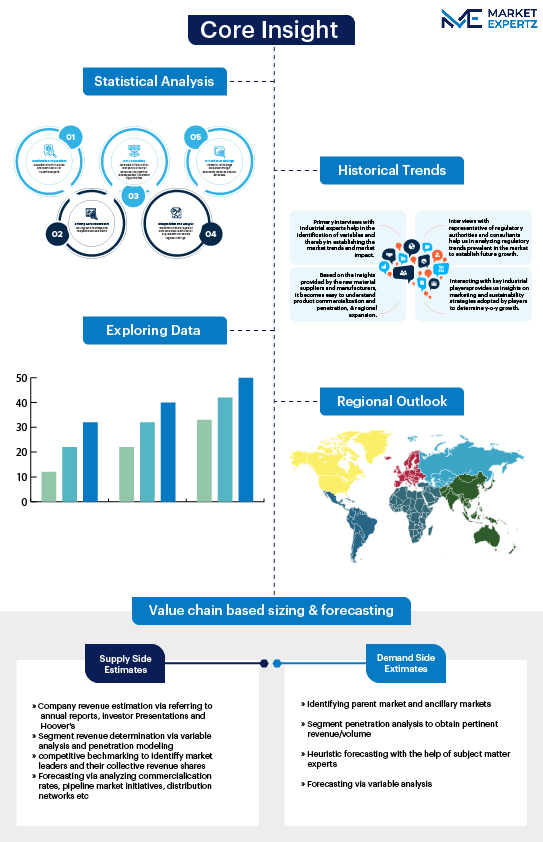

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"